Reflect Glass Magnetron Sputtering Coating Line

Magnetron Sputtering Glass Coating Production Line

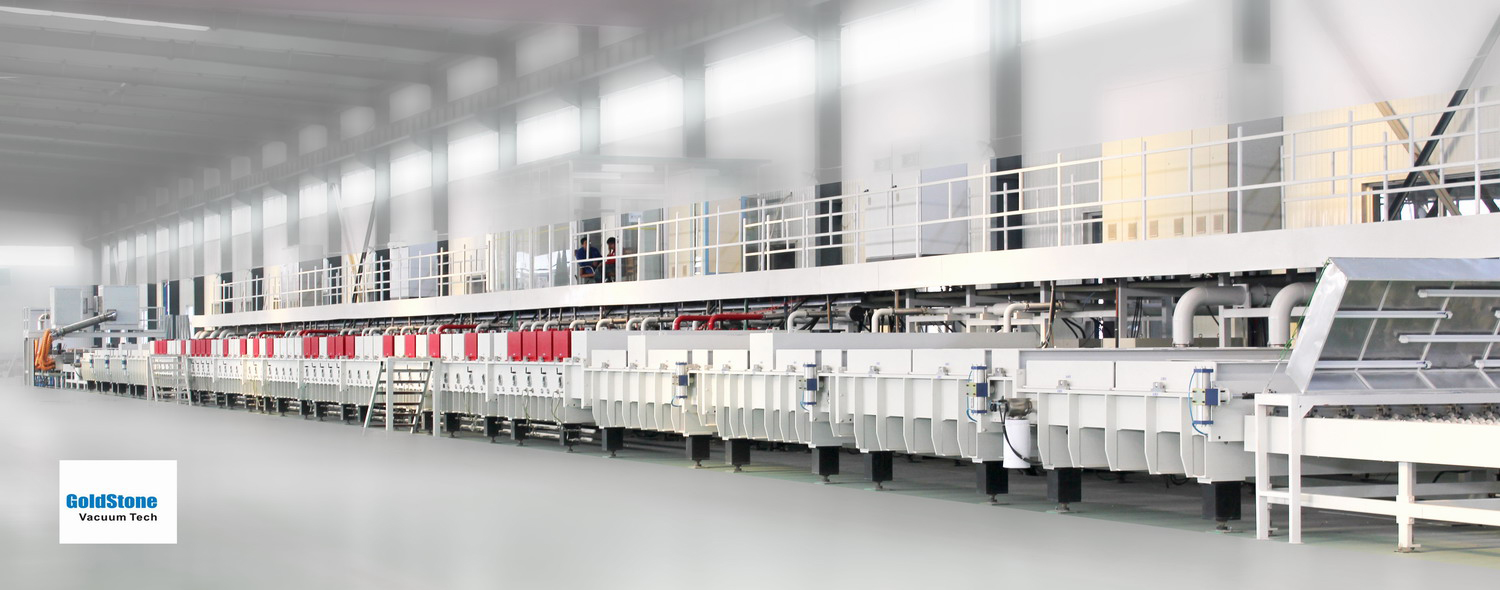

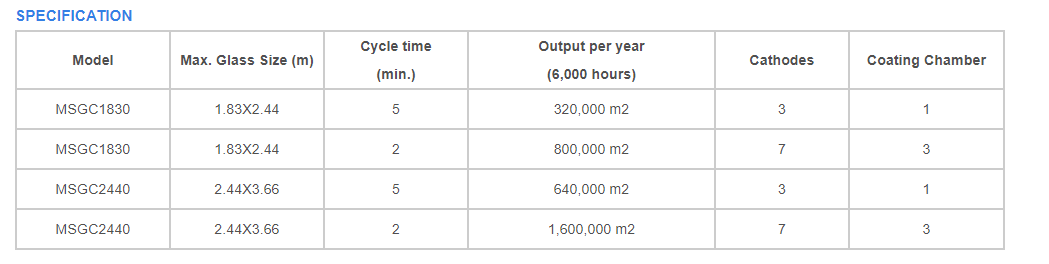

The magnetron sputtering coating system could be applied in either architecture reflective glass, or mirror and decoration colorful glass. The well designed large area sputtering cathode can make coating on glass with max. size of 2540×3660mm. The optimized design and precise manufacturing can guarantee to get a higher vacuum and a shorter cycle time by using a smaller pumping system. Modular design of the sputtering chamber, easy to achieve the multiple layers coating with different material and process gas.

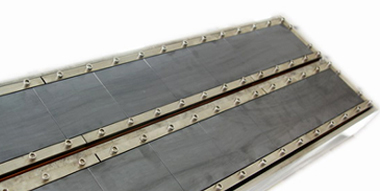

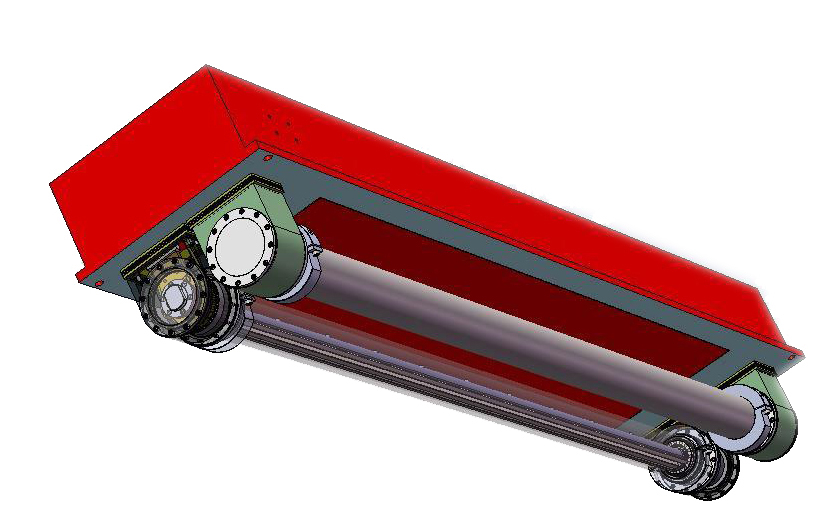

We provide types of sputtering cathode for customer for customer selection, such as planer cathode, rotary cathode and dual-mag cathode.

|

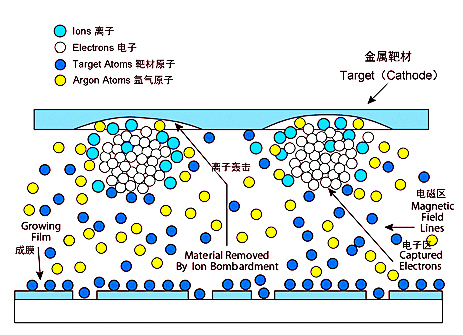

Sputtering Principle Sputtering" is a vacuum process used to deposit very thin films on substrates. It is performed by applying a high voltage across a low-pressure gas (usually argon at about 5 millitorr) to create a "plasma," which consists of electrons and gas ions in a high-energy state. (This is sometimes called a "glow discharge" process because the plasma emits a colorful halo of light.) During sputtering, energized plasma ions strike a "target", composed of the desired coating material, and cause atoms from that target to be ejected with enough energy to travel to, and bond with, the substrate. |  |

|

|

| Well Manufactured Vacuum Chamber More than 30 years' experience in vacuum machinery field helps engineers of Goldstone design the perfect vacuum chamber. Around Chengdu city in the Southwest of China, there located lots of famous military enterprise, such as aircraft factory, aeroplane engine factory, satellite factory and heavy industry. Those factories have the powerful machine tools and manufacturing ability. |

|

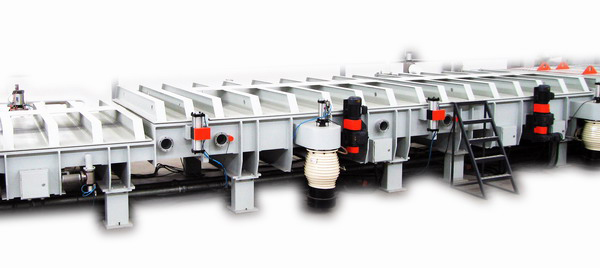

The chambers made by Goldstone have characters of well design, fine manufacturing, good sealing, as well economy and durance. The chamber is designed in modular, flexible for multi-coating and function expending.The vacuum system of production line is consist of many rooms, lock room, holding room, buffer room, sputter coating room and gas isolating room, the know-how vacuum lock mechanism is equipped on the machine to guarantee the high speed products coating process continuously. |  |

|

Advaced Magnetron Sputtering Technology More than 30 years' experience in vacuum machinery field helps engineers of Goldstone design the perfect vacuum chamber. Around Chengdu city in the Southwest of China, there located lots of famous military enterprise, such as aircraft factory, aeroplane engine factory, satellite factory and heavy industry. Those factories have the powerful machine tools and manufacturing ability. So it is no doubt that the best vacuum chambers in China are always made from this area. |  |

|

We can provide: ► DC Planar Sputtering ► DC Pulse Planar Sputtering ► Twin-mag Planar MF Sputtering ► Twin C-mag Rotary MF Sputtering ► RF Sputtering |  |

Such various different solution for customer selection depending on their demond formatierlals, coating thickness and products output. As well, we can supply the high quality sputtering coating target materials in the long term service for customers.

|  |

|---|

|

Effecient Vacuum Pump System From economy considering, we highly recommond to equip with Chinese high performance vacuum pump. After 40 years' developing on vacuum pump design and manufacturing, now China can make almost all kinds of vacuum pumps approch to top level in the world. Those pumps has good performance/price ratio, can definitely reduce the machine manufacturing cost, and they are proved qualified in most application fields such as metallization, glass coating, mirror coating and car spares and decoration coating. For high vacuum applications like Low-E glass coating, ITO coating, Solar film coating, Electric film and Optical film coating, the worldwide famous brand vacuum acquirement components are necessary to be selected. |  |

| Automatical Control The sputtering production line is a complex system which need to use the computer system to control all parts automatically. The system is consisted of industry PC, PLC, touch screen operation panel and pro-bus. The operator could monitor all equipments status and process parameters from the main panel. Setting all parameters into the program, then the machine can controlled by computer and achieve the production fully automatically. 50 groups of parameters and process could be restored by customer and you can recall them in any time to repeat the products. |

Professional Support and Service Goldstone provide customers with professional technical supporting, customizing machinery, complete technical transfering and turn-key solution. If you have technical questions need our consulting or you want to upgrade your existed machinery or you want to purchase some spare parts for vacuum coating machine, you are welcome to contact with us. |  |