Low-E Glass Coating Production Line

What is Low-E Glass?

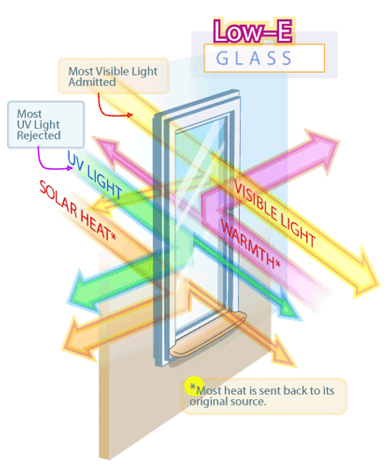

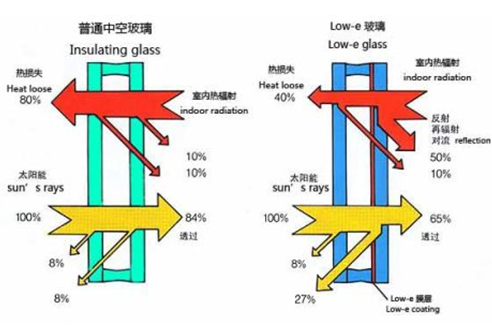

Low-E glass means the Low-Emissivity Glass which is a type of energy-efficient glass for building. In general the energy of sunlight, infrared heat holds about 51.2%, visible light occupies about 46.8% of the heat, ultraviolet and other rays occupy about 2%, so infrared light is basically heat. The traditional coating glass and colored glass are mainly based on reflection and absorption of visible light. But Low E glass has the ability to allow visible light to pass through glass while blocking certain amounts of UV light and IR light. So its optical performance is greatly improved.

Low-E glass works by reflecting heat back to its source. It does this by utilizing a special coating which has a poor emissivity of heat and does not allow heat to be transferred through it. In the summer this helps to keep your house cooler, as the heat from objects outside is kept outside. In the winter, all objects in your home are heated (by either the sun or your furnace). This heat is also bounced back into your house by the Low-E glass. Therefore the Low-E coating glass can keep your room warm or cold, then reduce the amount of energy lost through your windows up to 75%!

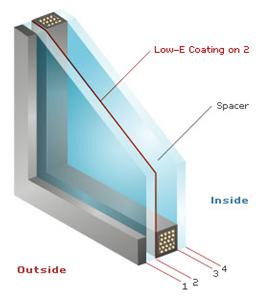

There are two types of Low-E glass: hard coating and soft coating. Hard coating is the online process during glass producing, which makes Tin molten directly on the glass. The soft coating is the offline process, by the vacuum magnetron sputtering coating machine, which has better heat insulation rate because of using the multiple metal layers include silver, and the quality of Low-E film is easiler to be controlled, so the soft coating Low-E glass becomes the more popular products now. Soft coating Low-E glass is always sandwiched with another piece of glass to prevent metal layer being oxidated.

Magnetron Sputtering

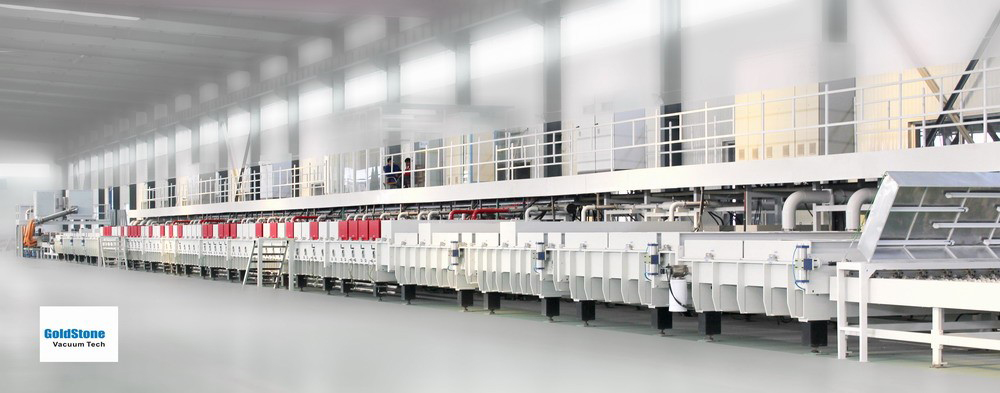

Production Line for Low-E Glass

Since 2003, made the first Low-E sputter coating line in China, Goldstone’s engineers have more than ten years experience in design and manufacturing high quality Low-E coating system.

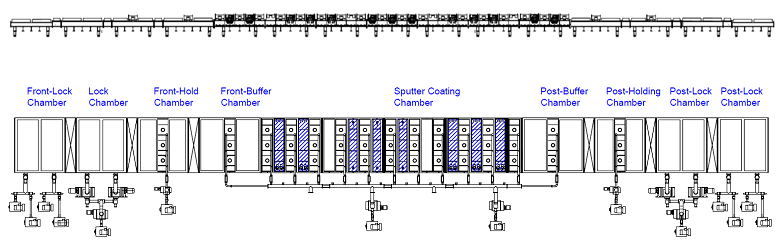

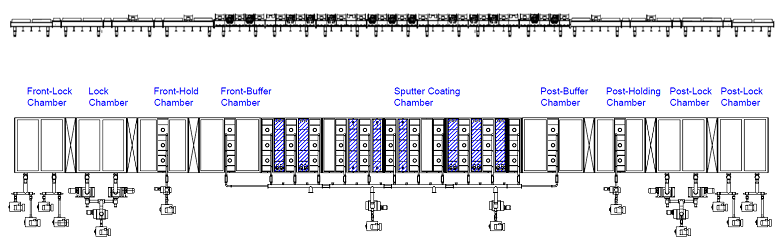

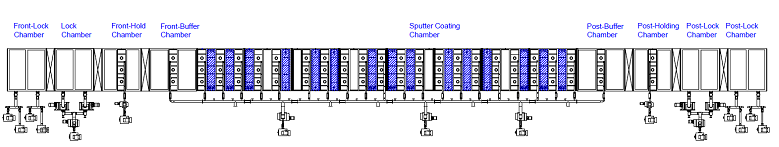

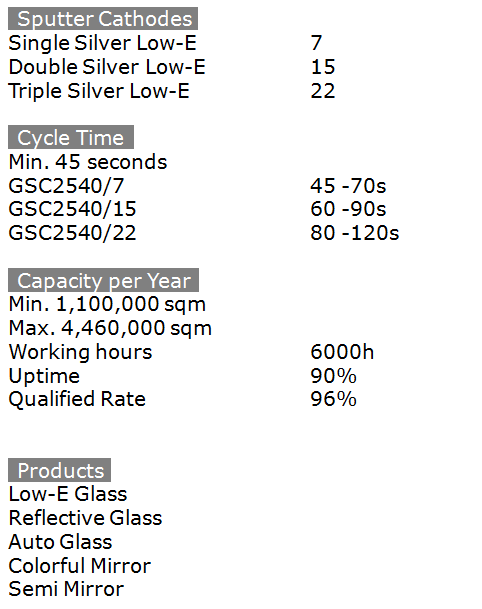

GSC2540 Series Low-E Magnetron Sputter Coating Line

Single Silver Low-E, 7 Sputter Cathodes

Double Silver Low-E, 15 Sputter Cathodes

Triple Silver Low-E, 22 Sputter Cathodes

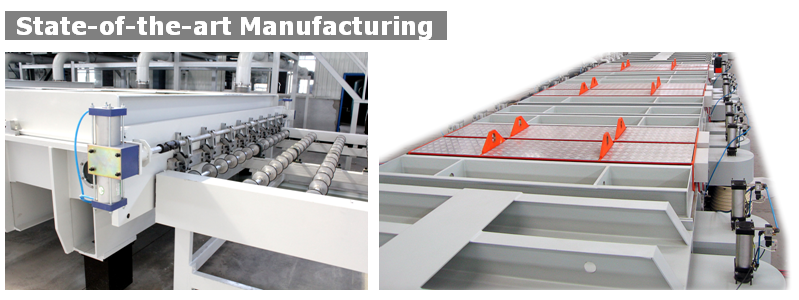

Based on decades experiences in large area vacuum coating system, Goldstone can design and manufacturing the complex and flexible vacuum chambers according to the requirement from customers. The chambers are made by professional manufacturers using advanced CNC machine tools.

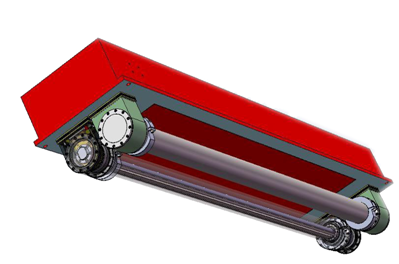

The rotary sputter cathode has many advantages compared with planar sputter cathode, such like:

Higher utilization rate of target material

Higher applicable sputter power and increasing of sputter rates

Stability working in AC power supply (less arcing and poisoning)

Flexibility in target materials including metal, metal oxide and ceramic targets

Therefore the dual rotary cathode is the best selection of Low-E glass magnetron sputtering line for oxide and semi-conductive layers.

Goldstone vacuum can design and manufacture the dual rotary sputter cathode for our customers. There are ten sets of Low-E coating machine had equipped with Goldstone’s rotatable cathodes for the past 15 years

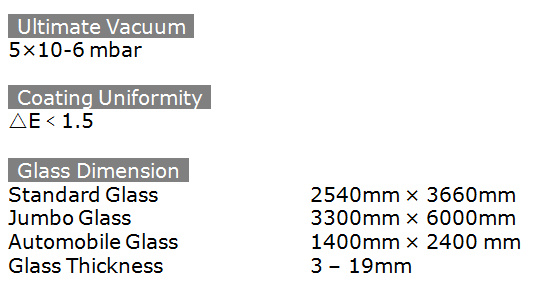

Equipped with high quality components from China, Europe and United States, the production line can guarantee to produce the high properties Low-E glass.

With more than 10 year experience of Low-E glass manufacturing at our Shanghai demonstration factory, Goldstone has developed the complete coating process, parameters and know-how for Low-E glass, either simple Low-E or double silver and triple silver Low-E products. Therefore, we can make the turn-key project for customer to transfer the Low-E technology together with the vacuum machine.