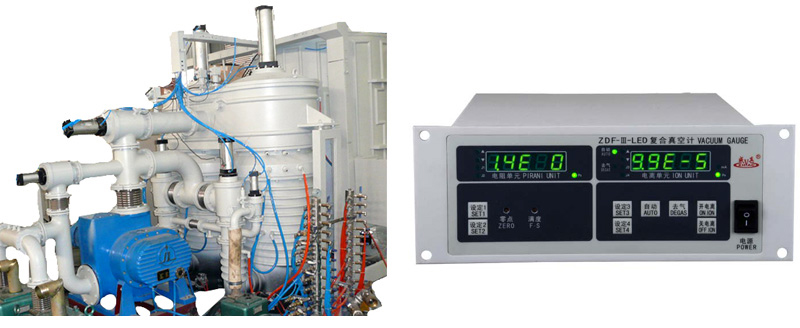

Optical lens coating is one of the major application of the vacuum chamber coating machine. Goldstone use worldwide advanced technology and high quality components to provide you the customizing and flexible total solutions.

We have supplied optical coating systems to many Chinese military companies and researching institute, the machine is well-know in the field.

The machine is applied on optical film and electric film coating process, the glass, polymer, plastic and ceramic could be the available substrate for coating.

With the diffirent components and module, the machine can produce various products like accuracy optical lens, glasses lens, IR filter, AR coating, wide band filter, cold reflector, ITO conductive film, CPL lens, VCD film and laser film, etc.

|

| |  |