Fiberglass Reinforced RTP Pipe

RTP Pipe Application

Reinforced thermalplastic pipe have been developed for a spoolable high pressure pipeline, it is used in some applications to instead of the steel pipe because of its advantage of:

Anti-corrosive

Flexible and Spoolable

High pressure up to 15 MPa

Easy installation with a 300-400 meters length in reel

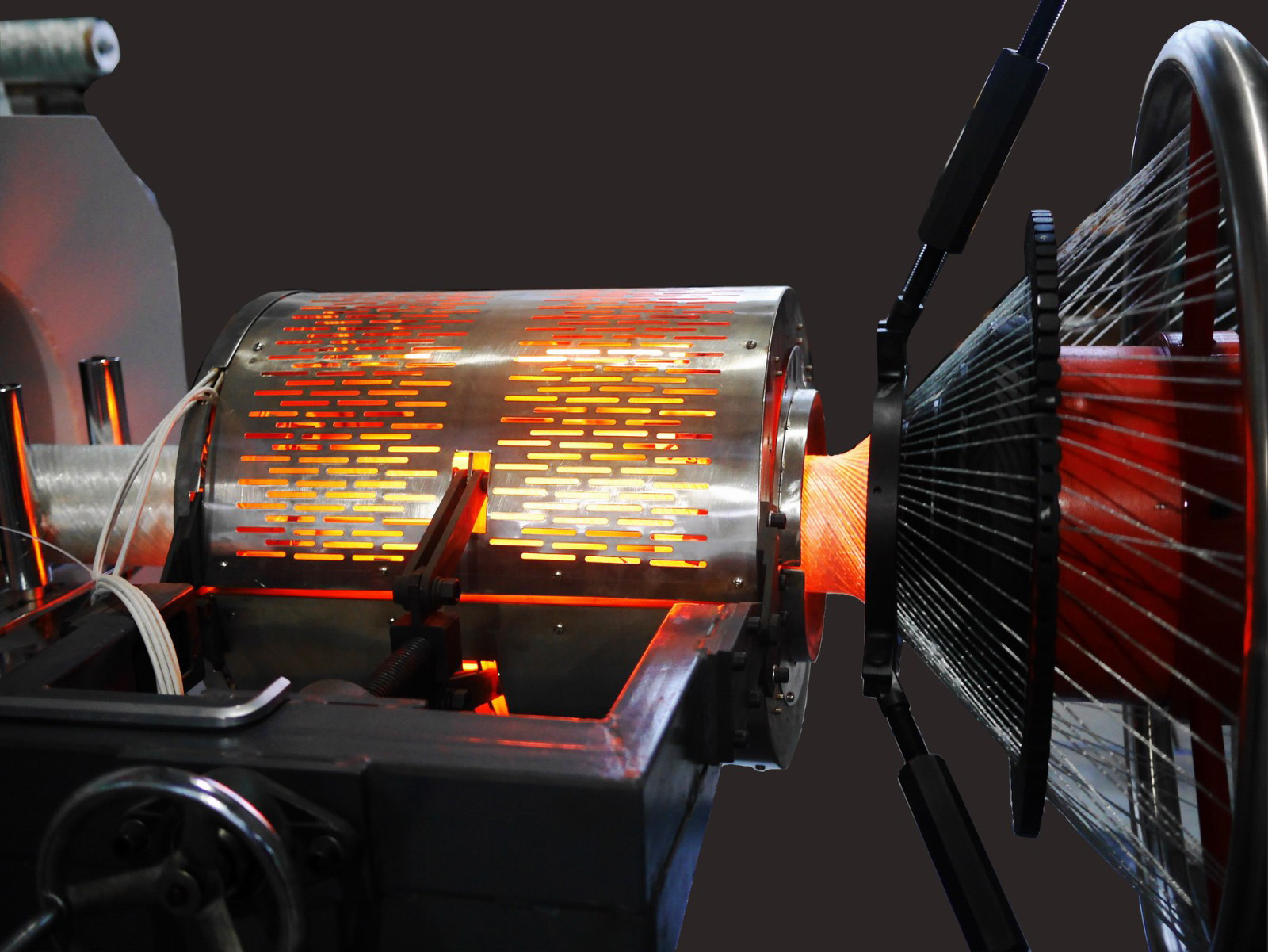

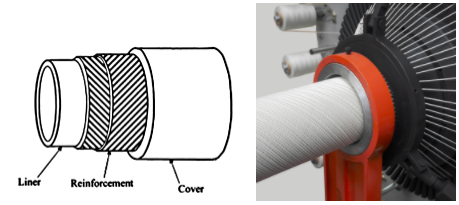

Structure of the RTP pipe

The basic sandwish structure of the RTP pipe is shown as the following figue which include the Liner tube, Reinforcement layer and Cover layer.

Liner tube can be selected for different applications like chemical corrosive, abrasion resistance, temperature resistance, etc. So you can use HDPE, PERT, PEX, PA, UHMWPE, such kind of materials to be the material of the functional tube.

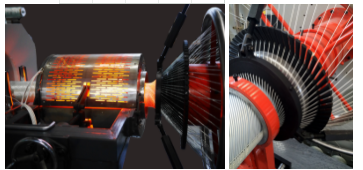

The reinforced layer provide the main pressure against for the RTP pipe. There are some kinds of reinforcement could be selected, like aramid fiber, fiberglass roving, polyester fiber, steel cord...

The outer cover layer gives the protection of the pipe.

Reinforcement Material

The impregnated treatment fiberglass roving is used as the reinforcement, and it is packed in a standard bobbin with bigger diameter about DN300. The glass should select S-glass or E-glass grade. Weight of each bobbin is about 10-12kg, and length is about 2500-3000 meters, tensile of dry fiber is about 0.50N/tex, and after impregnated treatment the single filament tensile is average 2200-2300N. The impregnation material is a kind of polyethylene friend material which has good bonding surface between PE and fiber. One bobbin can produce 1400-1700 meters pipe, working for about 10 hours.

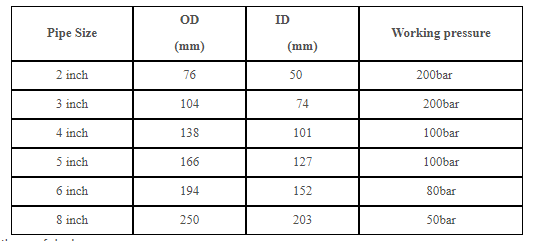

RTP Pipe Specification

Burst pressure is at least 3 times of design pressure.

RTP pipe jointing system

Goldstone Company has developed crimp and expansion fittings which allows efficient joining directly to steel lines, standard flanged connections, or other RTP pipelines. Recently, Goldstone team are working on design and manufacture new swaging machine, there would be more pipe jointing options for our customers.

The Goldstone Company fitting is a metallic device that mechanically fastens to the pipe. The fitting can terminate the pipe with a standard ASME B16.5 lap-joint flange or a weld neck transition. The fitting consists of a mandrel which is inserted into the pipe, and a sleeve which is crimped around the pipe. The mandrel and sleeve are both equipped with uni-directional teeth that securely grip the liner and jacket of the pipe.

Fittings are installed using specialized installation equipment that energizes the fitting. The energizing force creates a clamping pressure that holds the pipe in place and provides a seal between the thermoplastic liner and the fitting. For additional seal reliability the fitting is equipped with two o-rings. The fitting system does not require the application of heat or adhesives.